Hydraulic valves are the brain of the system. They control the

direction, pressure, and flow rate of the fluid, ensuring the machine operates as

desired. In this guide, we examine in detail the valve types used in industrial

applications, their working principles, and selection criteria.

Basic Knowledge

Hydraulic valves are divided into three main

categories:

Directional Control Valves, Pressure Control

Valves,

and

Flow Control Valves. Each category offers solutions for different

system needs.

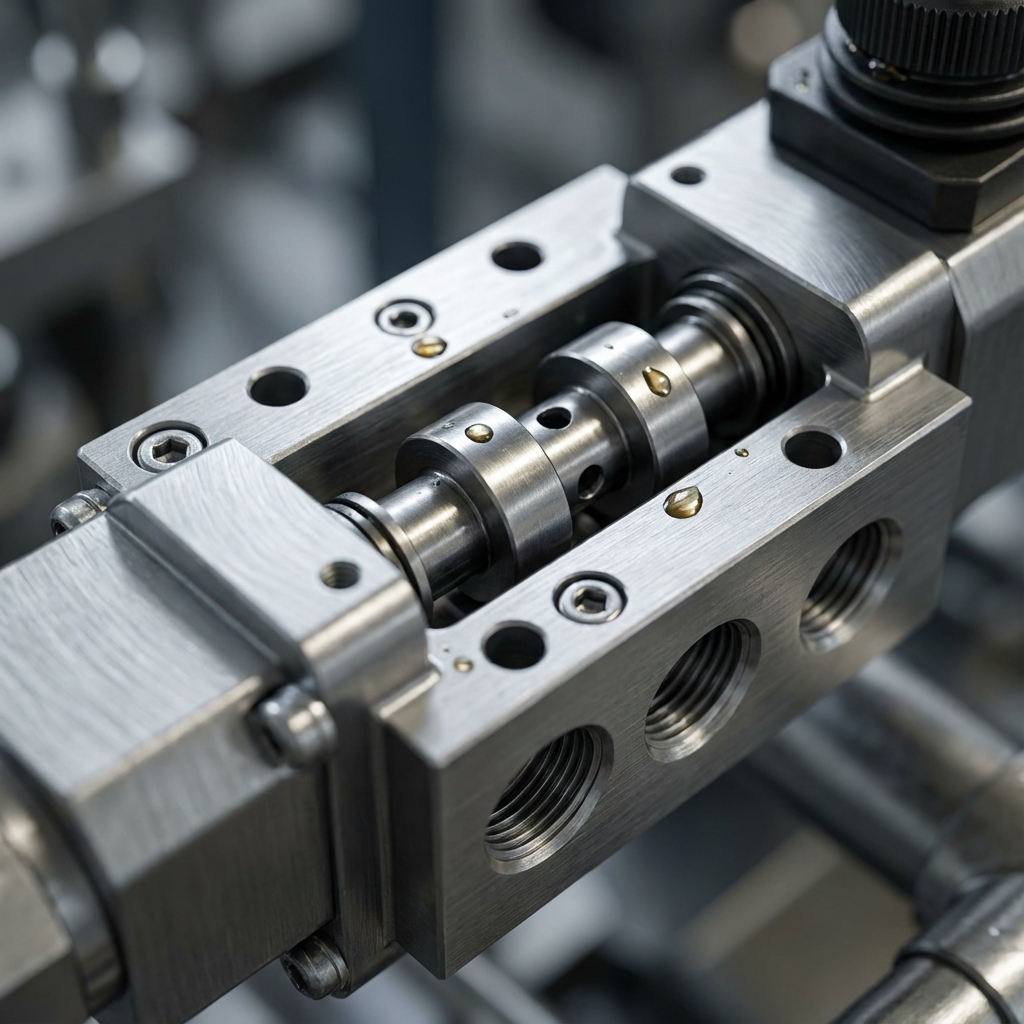

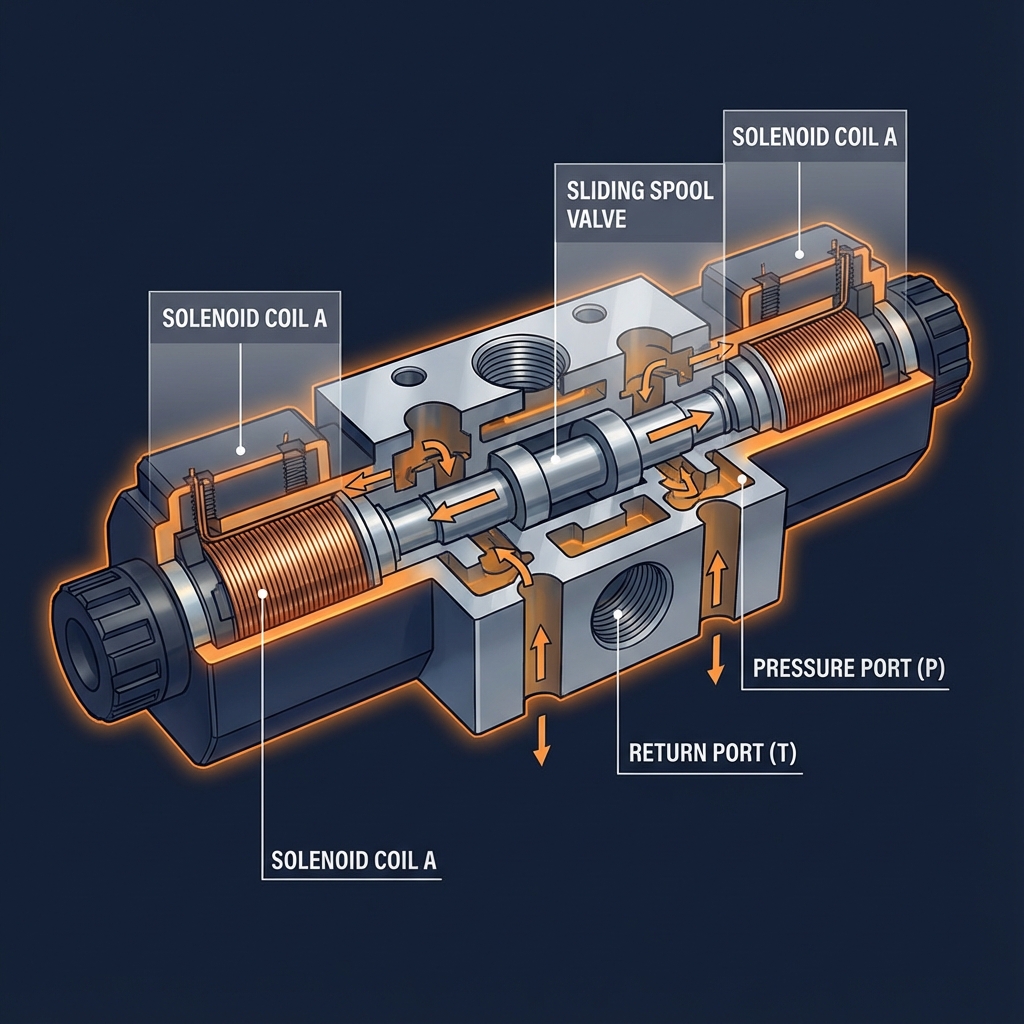

1. Directional Control Valves

Directional control valves determine where the hydraulic fluid goes in the system.

Basic functions such as the forward-backward movement of the cylinder and the direction

of rotation of the motor are provided by these valves.

1.1. Valve Definitions

Valves are defined in the format number of ports/number of positions.

For example,

4/3 valve: Means 4 ports (P, T, A, B) and 3 positions.

| Valve Type |

Positions |

Typical Application |

| 2/2 Valve

|

Open/Closed

|

Simple ON/OFF

control |

| 3/2 Valve

|

3 ports, 2

positions |

Single acting

cylinders |

| 4/2 Valve

|

4 ports, 2

positions |

Double acting

cylinder, continuous |

| 4/3 Valve |

4 ports, 3 positions |

Double acting cylinder, center position |

1.2. Actuation Types

- Solenoid

(Electric): Ideal for automation systems, fast response

- Manual

(Lever/Pedal): Applications requiring operator control

- Pilot

Operated: For high flow systems

- Proportional:

Precision position and speed control

"The valve is the brain of the system. Providing precise control with proportional

and servo valves is the cornerstone of modern hydraulics."

— BRS PROSES Engineering Team

2. Pressure Control Valves

Pressure control valves limit, regulate, or redirect pressure in the system.

They are critically important for safety and performance.

2.1. Main Pressure Valves

- Relief Valve: Limits maximum system

pressure, discharges to tank line in case of overpressure

- Pressure Reducing Valve: Provides lower

pressure

in a specific line

- Sequence Valve: Activates the secondary circuit

when a certain pressure is reached

- Counterbalance

Valve:

Provides control in cylinders pulled by the load

Critical Warning

A hydraulic system without a relief valve

must never be operated. Excessive pressure can lead to hose bursts,

seal damage, and serious injuries.

3. Flow Control Valves

Flow control valves adjust the speed of the fluid (flow rate). They are used for

cylinder

speed and motor speed control.

3.1. Flow Control Types

- Throttle Valve:

Simple flow restriction, pressure dependent

- Flow Control

Valve: Pressure-independent constant flow

- Flow Divider:

Distributes flow equally or proportionately

4. Advanced Valve Technologies

4.1. Proportional Valves

Proportional valves adjust position or pressure proportionally with an electrical

signal.

They work integrated with PLC control to provide precise automation.

4.2. Servo Valves

Servo valves are designed for applications requiring the highest precision.

They offer ±0.1mm position accuracy and ms level

response

times.

5. BRS PROSES Valve Solutions

As BRS PROSES, we offer comprehensive valve solutions for your

industrial

hydraulic systems:

- Standard and custom valve block

manufacturing

- Proportional and servo valve

integration

- Valve revision for existing

systems

- Technical consulting and

training

- Original spare parts supply