Correct hydraulic cylinder selection directly determines the

performance,

reliability, and life of the system. Incorrect sizing can lead to many problems, from

energy

waste to premature failures. In this technical guide, we share critical

engineering

parameters and calculation methods to consider in cylinder selection.

Basic Formula

F = P × A | Force (kN) =

Pressure (bar) × Area (cm²) ×

0.1

1. Basic Selection Criteria

Five basic parameters are determinants in hydraulic cylinder selection: required

force, stroke distance, operating

pressure,

movement speed, and operating environment.

Correct determination of these parameters is the prerequisite for optimum cylinder

selection.

1.1. Force Calculation

The first step is to determine the net force required by the application. Friction

losses,

load dynamics, and safety factor must be taken into account in calculations.

- Static

Load:Nominal

force is sufficient for constant loads

- Dynamic

Load:Acceleration force is added for moving loads

- Safety

Factor:Usually applied between 1.25-1.5

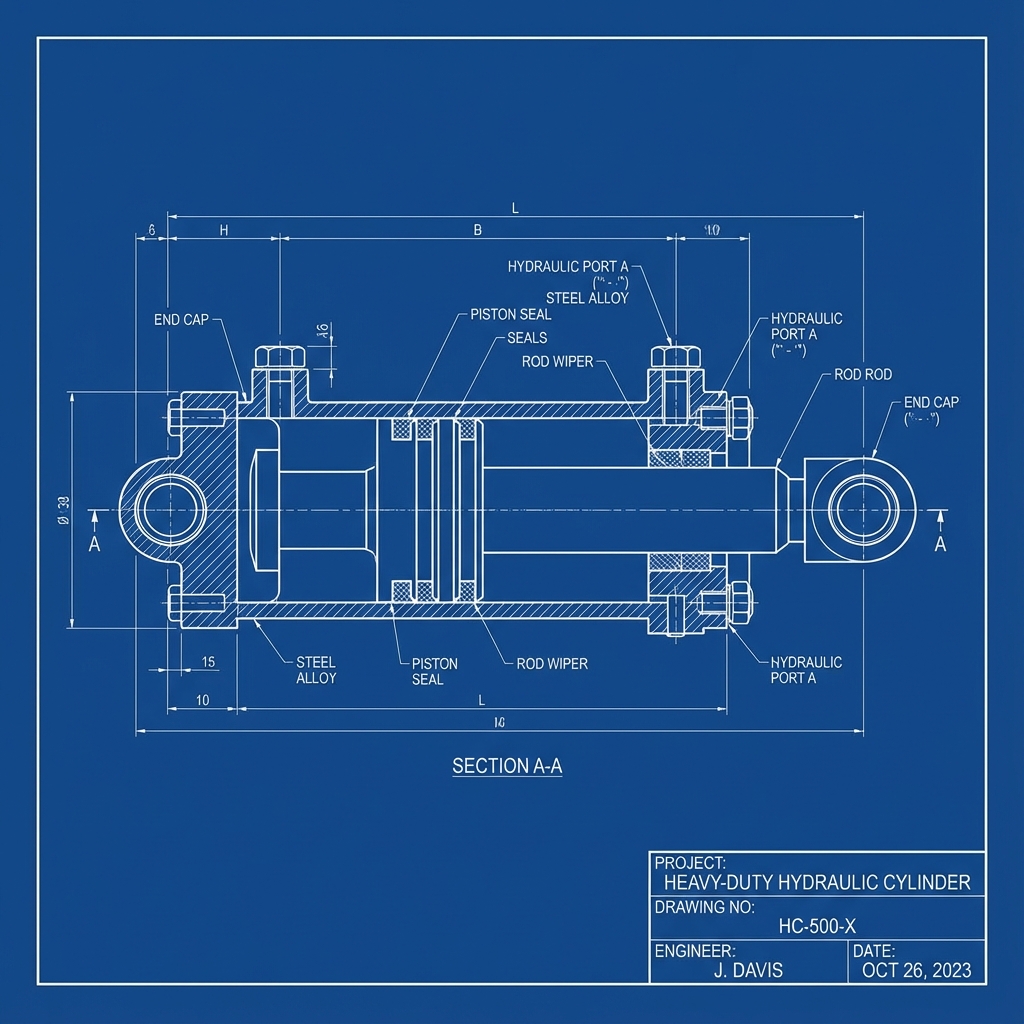

1.2. Determining Piston Diameter

After the required force and operating pressure are determined, the piston diameter is

calculated. As BRS PROSES, we manufacture cylinders in accordance with ISO

6020/1 and ISO 6022 standards.

| Piston Diameter (mm)

|

Piston Area (cm²) |

Force at 250 bar (kN)

|

Typical Application |

|

Ø40 |

12.57 |

31.4 |

Light precision |

|

Ø63 |

31.17 |

77.9 |

Medium duty presses |

|

Ø100 |

78.54 |

196.4 |

Heavy industry |

| Ø160 |

201.06 |

502.7 |

Press machines |

2. Stroke Distance

Stroke distance is the total distance the piston will move. When determining the stroke,

additional distance for application tolerances and position sensors should be taken into

account. Buckling control is mandatory for long-stroke cylinders (over

1000mm).

"Correct cylinder selection is the foundation of the project. Small errors in

diameter,

stroke, and pressure calculations turn into major performance losses."

— BRS PROSES Engineering Team

3. Operating Environment Assessment

Environmental Conditions Are Critical

The operating environment directly affects the

selection

of cylinder material and sealing elements. The following factors must be evaluated:

- Temperature Range: Standard between -20°C and

+80°C, special seals for extreme conditions

- Corrosive Environment: Stainless steel or

chrome

plating requirement

- Dust/Dirt:Rod protector and wiper selection

- Mounting

Position:Horizontal, vertical, or angled mounting requirements

4. Connection and Mounting Types

Cylinder mounting type should be selected according to the application.

Most common mounting types:

- Flange Mounting

(MF/MP):For fixed applications

- Articulated

(MT/MG):Places requiring angular movement

- Clevis Type

(MS/MH):For pivot connection

- Square Flange

(MF4/MF5):Heavy load applications

5. BRS PROSES Cylinder Selection Support

As BRS PROSES, we are with you in your hydraulic cylinder selection

with

over 25 years of experience. Our engineering team:

- Free technical consultancy

- Application-based cylinder

calculation

- ISO and ECO series standard

cylinders

- Custom design cylinder

manufacturing

- Fast delivery and technical

support